Anti freezing and thermal insulation measures for plant instruments and meters .

Update:Nov 23,2021

Summary:Thermal insulation measures for anti freezing methods of instruments and meters:1. Heat preservation with thermal insulation materials, that is, wrap ......

Thermal insulation measures for anti freezing methods of instruments and meters:

1. Heat preservation with thermal insulation materials, that is, wrap the parts of instruments that are easy to freeze or afraid of freezing with thermal insulation materials. When winter comes, check and discharge sewage frequently to prevent damage to the thermal insulation materials of the packaging.

2. Heat tracing measures steam heat tracing measures: that is, use pipe steam heating for heat preservation. Before thermal insulation and steam supply in winter, check whether the steam insulation pipeline is unblocked or blocked. It is better to pass the steam for 24 hours without being too hot. Sometimes, adjust the heat preservation steam supply according to the change of weather temperature, so as to prevent the vaporization of condensate in the pressure lead pipe of the transmitter due to too high temperature from affecting the operation of the transmitter, or the freezing of condensate in the pressure lead pipe of the transmitter due to too low temperature from affecting the smooth operation of the transmitter.

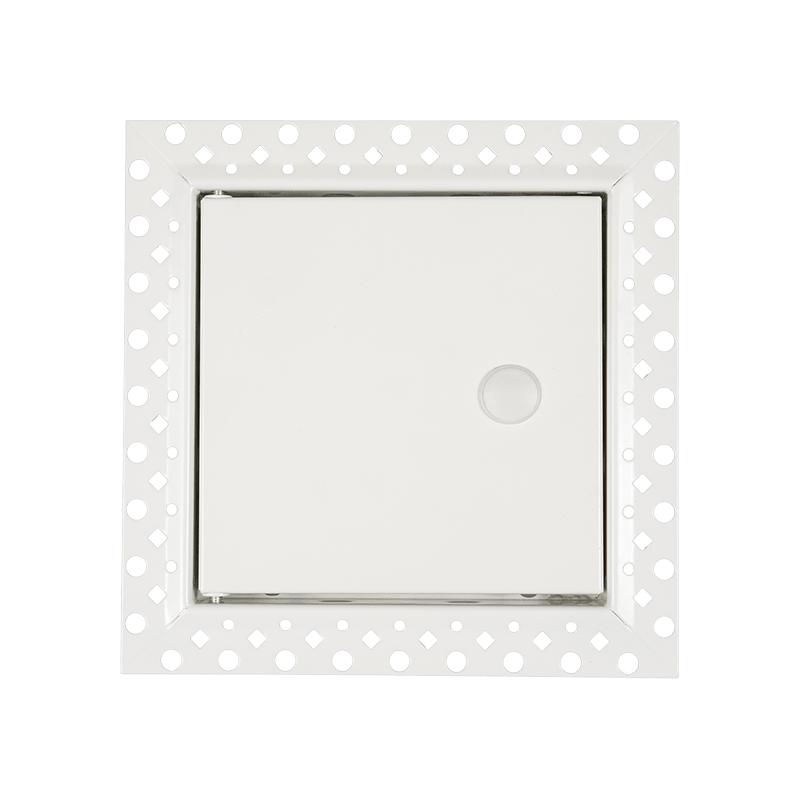

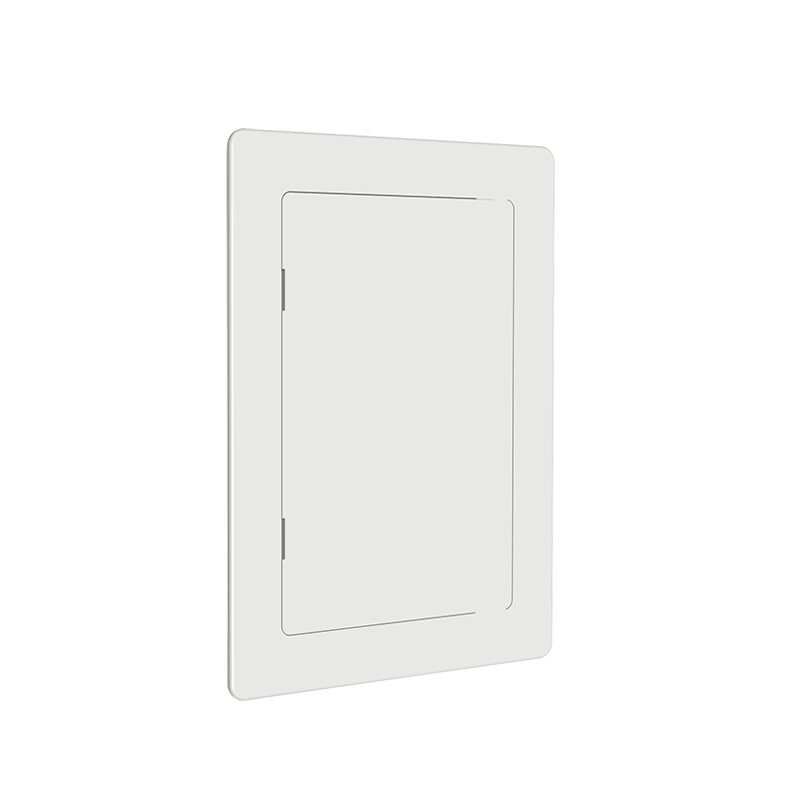

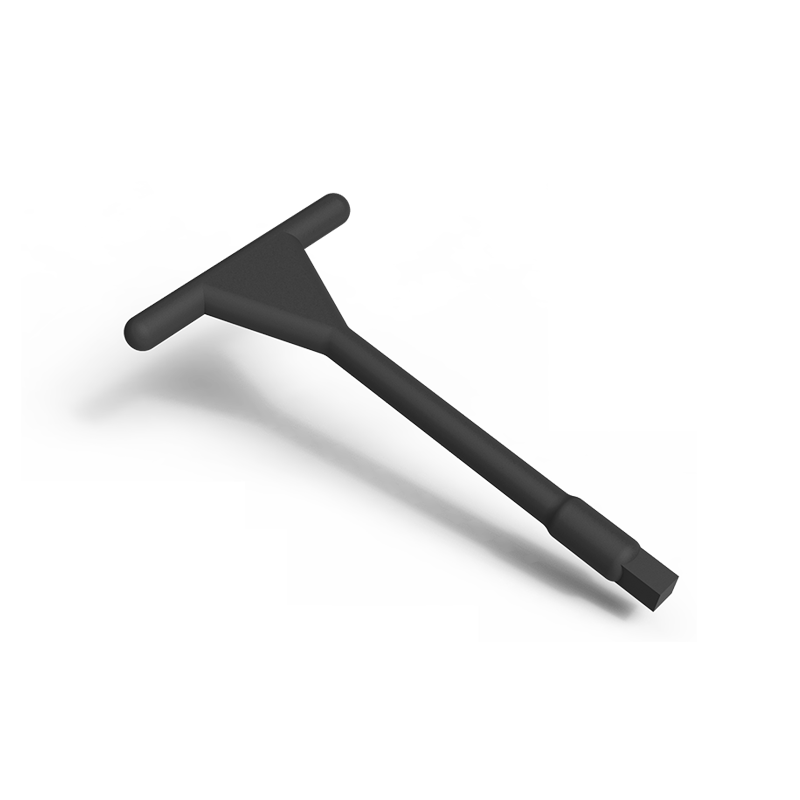

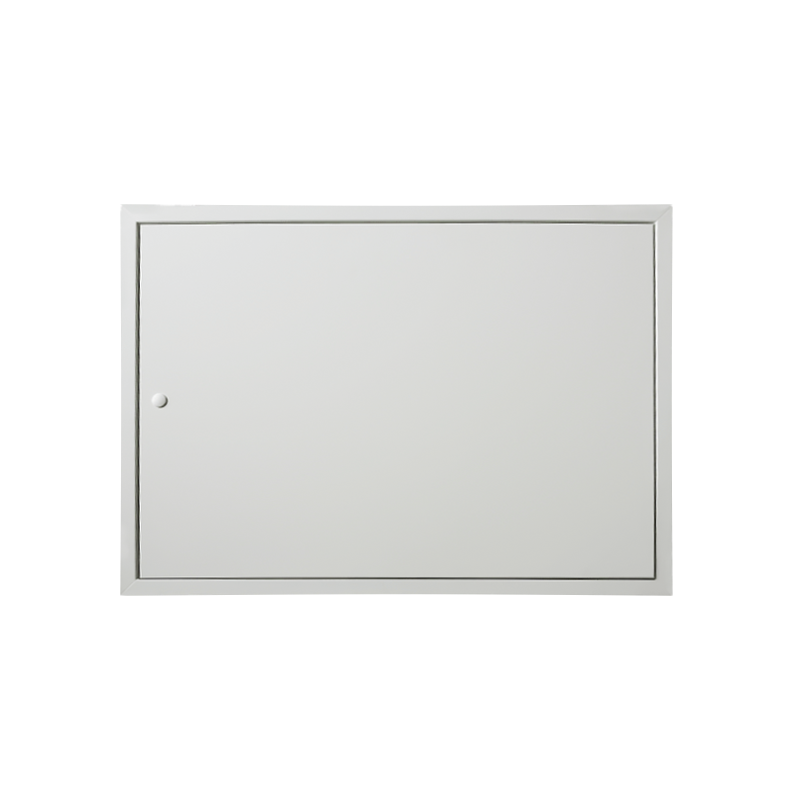

3. Measures for heat preservation and protection box: a. the heat tracing and insulation box of electric heating pipe is composed of three parts: box, heater and instrument bracket. Its structural form is the same as that of the protection box. The difference is that the box is equipped with electrical heating device, the heating device is composed of electric heating pipe and temperature controller, and the side of the box is equipped with socket. When the power is connected, the box is heated to the required temperature, Then the temperature controller turns on the power and continues to raise the temperature. Through repeated work, the temperature in the box can be maintained within a certain range. Main parameters of thermostatic heater:

(1) rated voltage: 200v.50hz; (2) rated power: 300 ~ 500W; (3) the control temperature can be set by the user; (4) thermostatic heater can also be made into explosion-proof type; (5) there are three kinds of electric heating pipe materials: copper pipe, carbon steel pipe and stainless steel pipe.

b. Steam pipe heat tracing insulation box, the heat tracing pipe is an S-shaped structure made of metal pipe. The upper and lower parts of the box are welded with the heat tracing pipe by welding through plate joints. The heat tracing pipe is installed in the box for upper in and lower out, and the purpose of heating is achieved through the circulation of steam in the tube cavity. The materials of heat tracing pipe are generally divided into two types: red copper pipe and seamless steel pipe (carbon steel).

c. A layer of insulation cotton is added to the key instrument box, and rubber seals are added at the door of the insulation box and the inlet and outlet pipelines to achieve better insulation and antifreeze effect of the instrument system.

English

English 简体中文

简体中文