Summary:The stand-alone dust collector is installed near the mechanical equipment that produces dust, and the user can configure metal or plastic dust suction......

The stand-alone dust collector is installed near the mechanical equipment that produces dust, and the user can configure metal or plastic dust suction pipes and dust hoods according to the size of the air inlet on the dust collector.

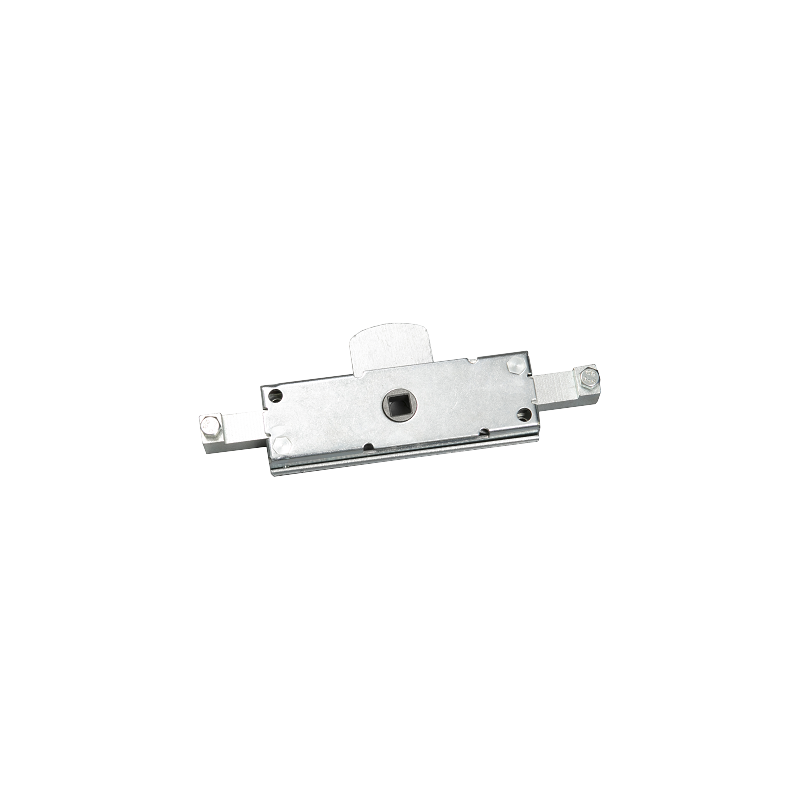

1. The electric control box cover of the single-unit dust collector should not be opened at will during work. If the cleaning time needs to be adjusted or the circuit needs to be checked, the power supply should be cut off after shutting down and working.

2. According to the nature and capacity of the dust, the stand-alone dust collector should be vibrated regularly to clean the dust. Generally, the dust collector should be vibrated three to four times per shift to ensure the normal operation of the dust collector.

3. The stand-alone dust collector regularly cleans and removes dust according to actual needs. When the dust in the dust collector is cleaned, you only need to open the sealed ash door and draw out the drawer when the fan and ash cleaning mechanism stop working.

4. In order for the baozheng dust removal equipment to be in the best working condition, it should be as close as possible to the source of dust, generally 1.5m to 2.0m*, the connecting pipe should be as short as possible, and the elbow should be minimized to avoid increasing the resistance loss.

5. The dust hood is the key accessory for the baozheng stand-alone dust collector unit to be in the best condition. The user should make the dust hood according to the nature of the outer size of the processed part and the principle of opening, closing, closing, sealing and designing the dust hood. The ideal vacuum hood.

6. Before the stand-alone dust collector works, check whether the inspection door, the ash outlet door, and the air pipe connection system are sealed to avoid leakage and reduce the dust collection effect.

7. The voltage of the single-unit dust collector is three-phase AC 380 volts. It can be used after the external wire on the single-unit dust collector is connected to the power source. At the initial rotation, pay attention to whether the fan is rotating (such as reverse, air volume Very small, need to change the power supply wiring).

The filter bag materials used in the boiler dust collector are polyester, nylon, polypropylene, propylene fiber, glass fiber, and polyamide fiber.

1. The heat-resistant temperature of polyester in the boiler dust collector can reach 135℃, but the alkali resistance is poor;

2. The heat-resistant temperature of nylon is 100-110℃, and the strength is high;

3. The heat-resistant temperature of polypropylene is about 100℃, and it can resist acid and alkali corrosion.

4. The heat-resistant temperature of acrylic fiber is 145℃, and the chemical properties such as acid resistance are good;

5. The heat-resistant temperature of glass fiber is 250℃, which has good acid resistance and poor alkali resistance;

6. The polyamide temperature-resistant filter bag can withstand the highest temperature of 220℃, and has good acid and alkali resistance.

English

English 简体中文

简体中文