Summary:Sheet metal refers to a metal plate with uniform thickness defined by manual stamping or deformation. At the same time, some adjustment processes have......

Sheet metal refers to a metal plate with uniform thickness defined by manual stamping or deformation. At the same time, some adjustment processes have been added to make it a more complex manufacturing product.

Sheet metal processing typically includes cutting, blanking, bending, welding, and surface treatment. The equipment used includes presses, bending machines, welding machines, etc. With the progress of science and technology, sheet metal processing technology has also been improved, and more CNC processing equipment has been applied to sheet metal processing, such as CNC bending machines, CNC punching machines, CNC laser cutting, OTC welding equipment, etc. It has replaced traditional manual rough cutting, bending, polishing, and other equipment.

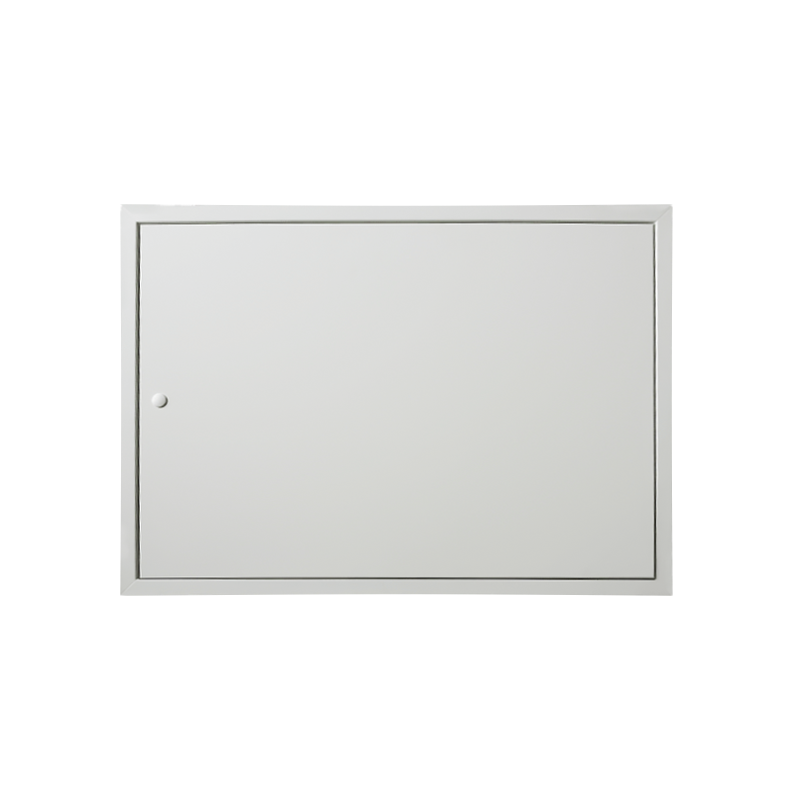

With the development of social economy, people have put forward higher requirements for sheet metal processing products. For example, the equipment shell should have a smooth, beautiful, and rust resistant effect. During the processing process, processes such as electroplating, polishing, and baking paint need to be performed on the surface of the metal plate.

Metal plate processing technology refers to the processing of metal plates by hand or mold to form target shapes and dimensions, and the formation of more complex shaped finished products through welding or machining. The main processes of sheet metal processing include blanking, bending, welding, surface treatment, and assembly.

With the continuous improvement of the development level of China's mechanical industry, the complexity of sheet metal parts is becoming higher and higher, and the processing requirements for sheet metal parts are also becoming higher and higher. Different sheet metal structures need to be designed in different forms. This design is non fixed and patternless, which poses more problems for sheet metal processing and has become a specific difficulty in improving sheet metal processing technology.

English

English 简体中文

简体中文